I-Blow molding, eyaziwa nangokuthi i-hollow blow molding, iyindlela yokucubungula ipulasitiki ekhula ngokushesha.Phakathi neMpi Yezwe Yesibili, inqubo yokubumba igalelo yaqala ukusetshenziselwa ukukhiqiza izitsha ze-polyethylene eziphansi.Ngasekupheleni kwawo-1950, lapho kuzalwa i-polyethylene ephezulu kakhulu kanye nokuthuthukiswa kwemishini yokubumba i-blow, ubuchwepheshe bokubumba busetshenziswa kabanzi.Umthamo weziqukathi ezingenalutho ungafinyelela ezinkulungwaneni zamalitha, futhi ukukhiqizwa okuthile kusebenzisa ukulawula kwekhompyutha.Amapulasitiki afanele ukubunjwa kokushaywa ahlanganisa i-polyethylene, i-polyvinyl chloride, i-polypropylene, i-polyester, njll. Iziqukathi ezingenalutho eziwumphumela zisetshenziswa kabanzi njengeziqukathi zokupakisha zezimboni.Ngokwendlela yokukhiqiza ye-parison, ukubunjwa kwe-blow kungahlukaniswa ku-extrusion blow molding kanye ne-injection blow molding.Ezisanda kuthuthukiswa ziyi-multi-layer blow molding kanye ne-stretch blow molding.

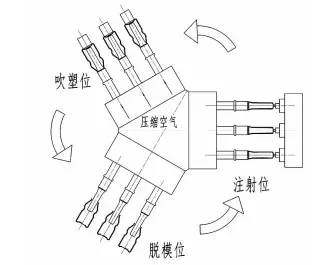

I-injection stretch blow blowing

Njengamanje, ubuchwepheshe bokubumba i-injection stretch blow busetshenziswa kakhulu kunokubumba umjovo.Le ndlela yokubumba i-blow iwukubumba i-injection blow, kodwa ikhulisa kuphela ukungezwani kwe-axial, okwenza ukubumba i-blow kube lula futhi kunciphise ukusetshenziswa kwamandla.Ivolumu yemikhiqizo engacutshungulwa ngokudwetshwa komjovo nokuvunguza inkulu kunaleyo ngokufutha ngomjovo.Ivolumu yesiqukathi esingavuthwa ngu-0.2-20L, futhi inqubo yayo yokusebenza imi kanje:

1. Umgomo wokubumba umjovo uyafana nowokubumba umjovo ojwayelekile.

2. Bese uphendulela i-parison ohlelweni lokulawula ukushisa nokushisa ukuze wenze i-parison ithambe.

3. Jikela esiteshini sokudonsa bese uvala isikhunta.I-push rod in the core yelula i-parison eduze ne-axial direction, kuyilapho ishaya umoya ukwenza i-parison ibe eduze nodonga lwesikhunta futhi ipholile.

4. Dlulisela esiteshini sokudiliza ukuze uthathe izingxenye

Inothi - ukudonsa - inqubo yokufutha:

Ipherishi lokubumba lomjovo → igumbi lokushisisa → ukuvala, ukudweba nokufutha → ukupholisa nokuthatha izingxenye

Umdwebo wohlelo lwesakhiwo somshini womjovo, ukudweba nokufutha

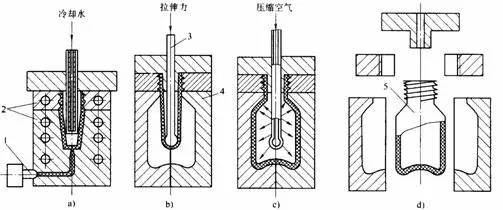

I-Extrusion blow molding

I-Extrusion blow molding ingenye yezindlela zokubumba ezisetshenziswa kakhulu.Ukucutshungulwa kwayo kubanzi kakhulu, kusukela emikhiqizweni emincane kuya ezitsheni ezinkulu nezingxenye zezimoto, imikhiqizo yamakhemikhali asemkhathini, njll. Inqubo yokucubungula imi kanje:

1. Okokuqala, ncibilikisa futhi uhlanganise irabha, futhi ukuncibilika kungena ekhanda lomshini ukuze kube i-parison ye-tubular.

2. Ngemva kokuba i-parison ifinyelele ubude obunqunyiwe ngaphambili, isikhunta sokubumba sivaliwe futhi i-parison iboshwe phakathi kwezingxenye ezimbili zesikhunta.

3. Vuthela umoya, vuthela umoya egcekeni, vuthela i-parison ukulenza libe seduze nendawo yokubunjwa.

4. Imikhiqizo yokupholisa

5. Vula isikhunta futhi ususe imikhiqizo eqinile.

Inqubo yokubumba i-Extrusion blow:

Ukuncibilika → i-extruding parison → ukuvala isikhunta nokuvuthela → ukuvulwa kwesikhunta kanye nokuthatha ingxenye

Umdwebo ohleliwe wesimiso sokubumba igalelo le-extrusion

(1 - inhloko ye-extruder; 2 - isikhunta sokushaya; 3 - i-parison; 4 - ipayipi lomoya elicindezelwe; 5 - izingxenye zepulasitiki)

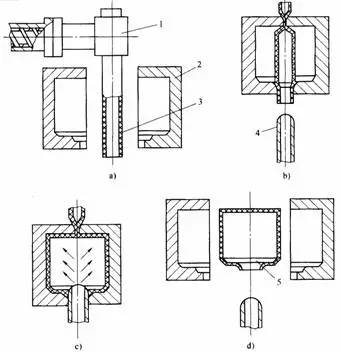

Ukubumba igalelo lomjovo

I-injection blow molding iyindlela yokubumba ehlanganisa izici zokubumba umjovo kanye nokubunjwa kokushaywa.Njengamanje, isetshenziswa ikakhulukazi emabhodleleni okuphuza, amabhodlela emithi kanye nezingxenye ezincane zesakhiwo ngokunemba okuphezulu.

1. Esiteshini sokubumba umjovo, umbungu wesikhunta ujovwa kuqala, futhi indlela yokucubungula iyafana naleyo yokubumba umjovo ojwayelekile.

2. Ngemva kokuvulwa kwesikhunta somjovo, i-mandrel ne-parison zithuthela esiteshini sokubumba i-blow.

3. I-mandrel ibeka i-parison phakathi kwesikhunta sokubumba futhi ivala isikhunta.Khona-ke, umoya ocindezelweyo uvunguza e-parison phakathi kwe-mandrel, bese ushaywa ukuze ukwenze usondele odongeni lwesikhunta futhi upholiswe.

4. Lapho isikhunta sivulwa, i-mandrel idluliselwa esiteshini sokudiliza.Ngemuva kokuthi ingxenye yokubumba igalelo ikhishwe, i-mandrel idluliselwa esiteshini sokujova ukuze ijikeleze.

Inqubo yokusebenza ye-injection blower:

Vuthela igceke lokubumba → ukuvuleka kwesikhunta sokujova esiteshini esifutha ifilimu → ukuvala isikhunta, ukubumba nokupholisa → ukuzungezisa esiteshini sokudiliza ukuze uthathe izingxenye → isonto

Umdwebo wohlelo lomgomo wokubumba igalelo lomjovo

Izinzuzo kanye nobubi bokubumba i-injection blow:

inzuzo

Umkhiqizo unamandla uma kuqhathaniswa nokunemba okuphezulu.Alikho ilunga esitsheni futhi asikho isidingo sokukhanda.Ukungafihli nokuqedwa kwangaphezulu kwezingxenye ezibunjwe ngokushaywa kuhle.Isetshenziselwa ikakhulukazi iziqukathi zepulasitiki eziqinile kanye neziqukathi zomlomo obanzi.

ukushiyeka

Izindleko zemishini yomshini ziphezulu kakhulu, futhi ukusetshenziswa kwamandla kukhulu.Ngokuvamile, kuphela iziqukathi ezincane (ngaphansi kuka-500ml) ezingakhiwa.Kunzima ukwenza iziqukathi ezinobumo obuyinkimbinkimbi kanye nemikhiqizo eyi-elliptical.

Noma ngabe i-injection blow molding, i-injection pull blow blow, i-extrusion pull blow blowing, ihlukaniswe yaba ukubumba okukodwa kanye nenqubo yokubumba kabili.Inqubo yokubumba yesikhathi esisodwa ine-automation ephezulu, ukunemba okuphezulu kwe-parison clamping kanye ne-indexing system, kanye nezindleko zemishini ephezulu.Ngokuvamile, abakhiqizi abaningi basebenzisa indlela yokubumba kabili, okungukuthi, ukubumba i-parison kuqala ngokubumba umjovo noma ngokukhipha umjovo, bese befaka i-parson komunye umshini (umshini wokujova noma umshini wokudonsa umjovo) ukuze ukhiphe umkhiqizo osuphelile, ophezulu. ukusebenza kahle kokukhiqiza.

Isikhathi sokuthumela: Mar-22-2023